Galvanized aluminum magnesium steel sheet

Galvanized aluminum magnesium steel plate is a new type of plate emerging in recent years,mainly is to improve the performance of galvanized sheet and replace high-end products.The composition of coating of galvanized aluminum magnesium steel plate contains the appropriate proportion of zinc,aluminum,magnesium and other metal elements to produce composite coating effect, thereby endowing the steel plate with a high degree of corrosion resistance,ammonia resistance,acid and alkali resistance and scratch resistance,so that it can still maintain its best condition under harsh environment,prolong its service life,promote resource conservation and protect the environment.

Keywords:

Category:

Product Description

Galvanized aluminum magnesium steel plate is a new type of plate emerging in recent years,mainly is to improve the performance of galvanized sheet and replace high-end products.The composition of coating of galvanized aluminum magnesium steel plate contains the appropriate proportion of zinc,aluminum,magnesium and other metal elements to produce composite coating effect, thereby endowing the steel plate with a high degree of corrosion resistance,ammonia resistance,acid and alkali resistance and scratch resistance,so that it can still maintain its best condition under harsh environment,prolong its service life,promote resource conservation and protect the environment.

Characteristics

1. Super Corrosion Resistance

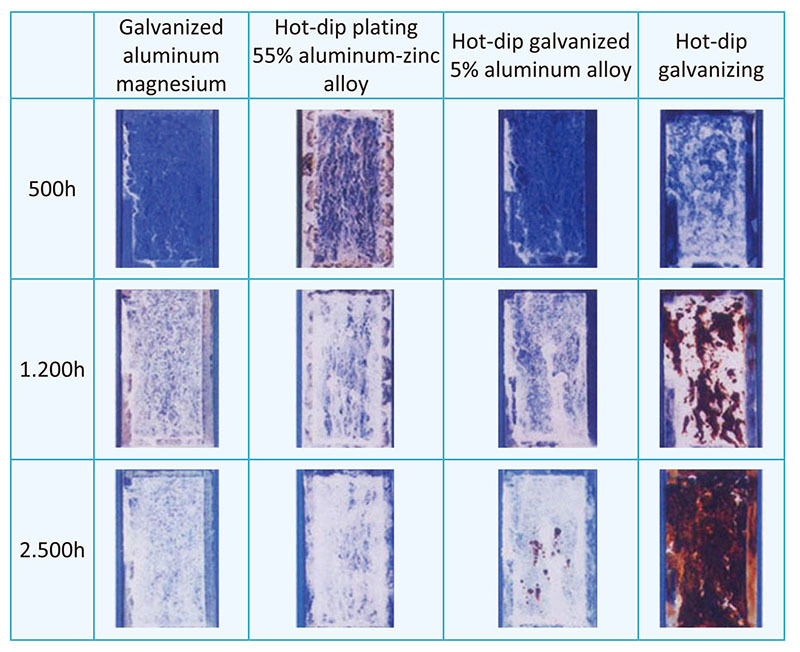

The alloy coating of galvanized Al-magnesium steel plate is formed by the high temperature curing of zinc (Zn),aluminum (A1) and magnesium (Mg).Its structure is composed of the dense ternary eutectic structure of Zn,AI and Zn2Mg,so that a dense protective film with extremely high adhesion can be formed on the surface of the steel plate that is to form effectively a barrier to prevent the penetration of corrosion factors.Although a protective film can also be formed on the surface of hot-dip galvanized steel plate,the layer of the coating is rather coarse,and corrosion factors such as water and oxygen are prone to corrosion through the protective film.Under the same coating premise,the corrosion resistance of zinc aluminum magnesium steel plate is 10-20 times that of general hot-dip galvanized steel plate,and 5-8 times that of hot-dip galvanized aluminum (5%) alloy steel plate.

-Saline Spray Test: Coating:90g/m2 (single side) without post: treatment

2. Ammonia Resistance

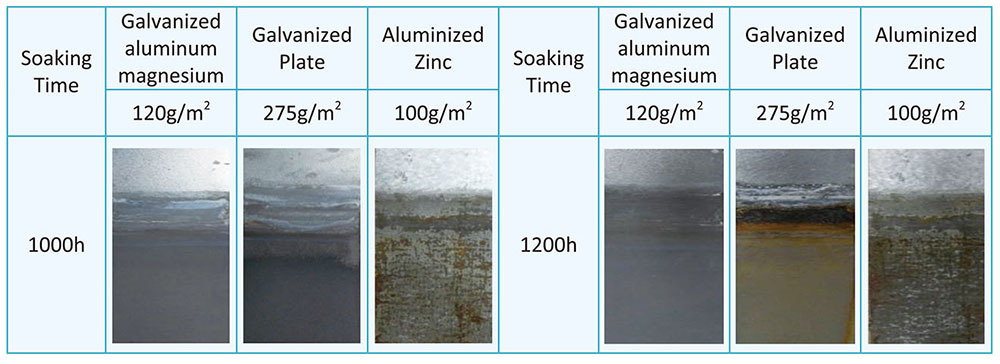

Galvanized aluminum-magnesium steel plate has better ammonia resistance than other hot- dip galvanized steel plates and hot-dip aluminum-plated (55%) zinc steel plates (soaked in 10% ammonia solution and replace the solution every 100 hours,soaking for a total of 400 hours,then confirming the condition of the plate)

*Red rust occurs in aluminized zinc plate after 400 hours, and sharp red rust occurs in galvanized plate after 1000 hours. However, no red rust occurs in galvanized aluminum magnesium plate even after 1200 hours,which is still in good condition.

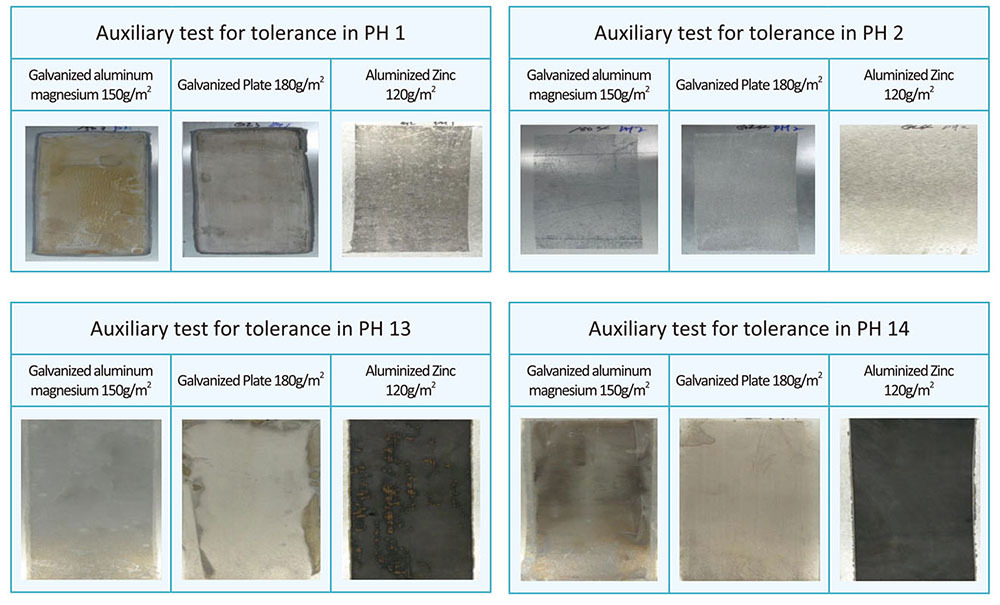

3. Acid and Alkaline Resistance

Compared with galvanized plate and aluminized zinc plate,under acidic and alkaline environment,galvanized aluminum magnesium steel plate has less coating reduction,with excellent chemical resistance. Galvanized plate in a strong acid with a PH value of 1-2,and aluminized zinc plate in a strong alkaline with a PH value of 13-L4,have poor chemical resistance, but galvanized aluminum magnesium has excellent chemical resistance,which can be used in agricultural animal husbandry and building materials,etc.

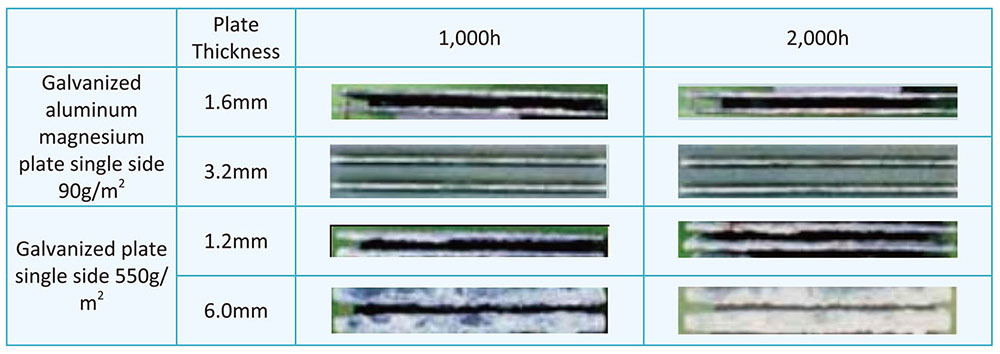

4. Fantastic Self-repair

The coating components around the cutting surface of the galvanized aluminum magnesium steel plate are also constantly dissolving,which generates a high-density protective film that is mainly composed of zinc hydroxide,partial alkali zinc chloride and magnesium hydroxide.This kind of protective film has a relatively low conductivity,which has obvious suppression actual effect on the etching of the cutting surface.

Corrosion Resistance Test of the Cross Section (results of brine spray test)

5. High Hardness and Wear Resistance

Tse ades i more than twie that of odnary goenred ste plale alo possesses super scratch resistance and wear resistance.

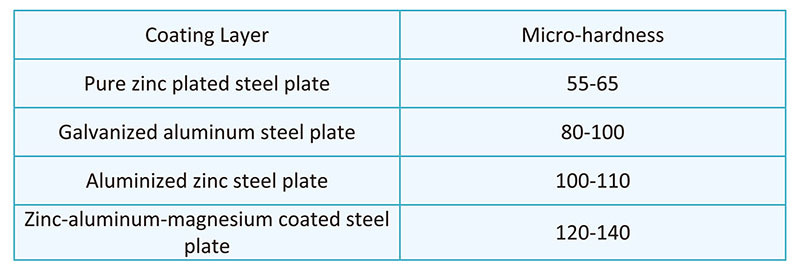

Hardness of galvanized aluminum magnesium steel plate

The microhardness of zinc-aluminum-magnesium coated steel plate can reach more than 120,while that of pure zinc coated steel plate is only 65.Therefore,the zinc-aluminum-magnesium coated steel plate has very good scratch resistance.

6. Green Environmental Protection

It does not contain Cr6+,which is harmful to the environment,and uses Cr3+ to achieve corrosion resistance.It is a very environmental-friendly material,complying with the RoHS standard of the European Union,and is currently internationally recognized as an environmental-friendly high-quality product.

7. Super Anti-rust Performance

For iron and steel substrate,when it is exposed in air water vapor,red rust will occur at the beginning.But because the coating is made of zinc,aluminum,magnesium alloy,zinc ions and magnesium ions can react with oxygen,forming a Simonkolleite protective layer,cutting off the contact between the cross section and the air water vapor ,finally achieving self-repair and corrosion termination effect,thus greatly improving the corrosion resistance and service life of the steel plate.Its anti-rust performance is 5-10 times that of ordinary galvanized plate.

8. Excellent Processing Performance

The spot welding process window of zinc-aluminum-magnesium steel plate is larger than that of pure zinc-coated steel plate.In laser welding of zinc-aluminum-magnesium steel plate,there is less coating spatter amount.Because of its good corrosion resistance,the coating weight of zinc-aluminum-magnesium coated steel plate can be half of that of the pure zinc coated steel plate,which helps to further improve the welding performance.Therefore,aluminum-zinc-magnesium steel plate has excellent tensile,stamping, bending,welding and other processing properties. when processed,it's not easy to produce tripping phenomenon.

9. Super Cost-effective

Multi performance meets or exceeds the standard of stainless steel,but the price is much lower than stainless steel.

10. Wide Range of Applications

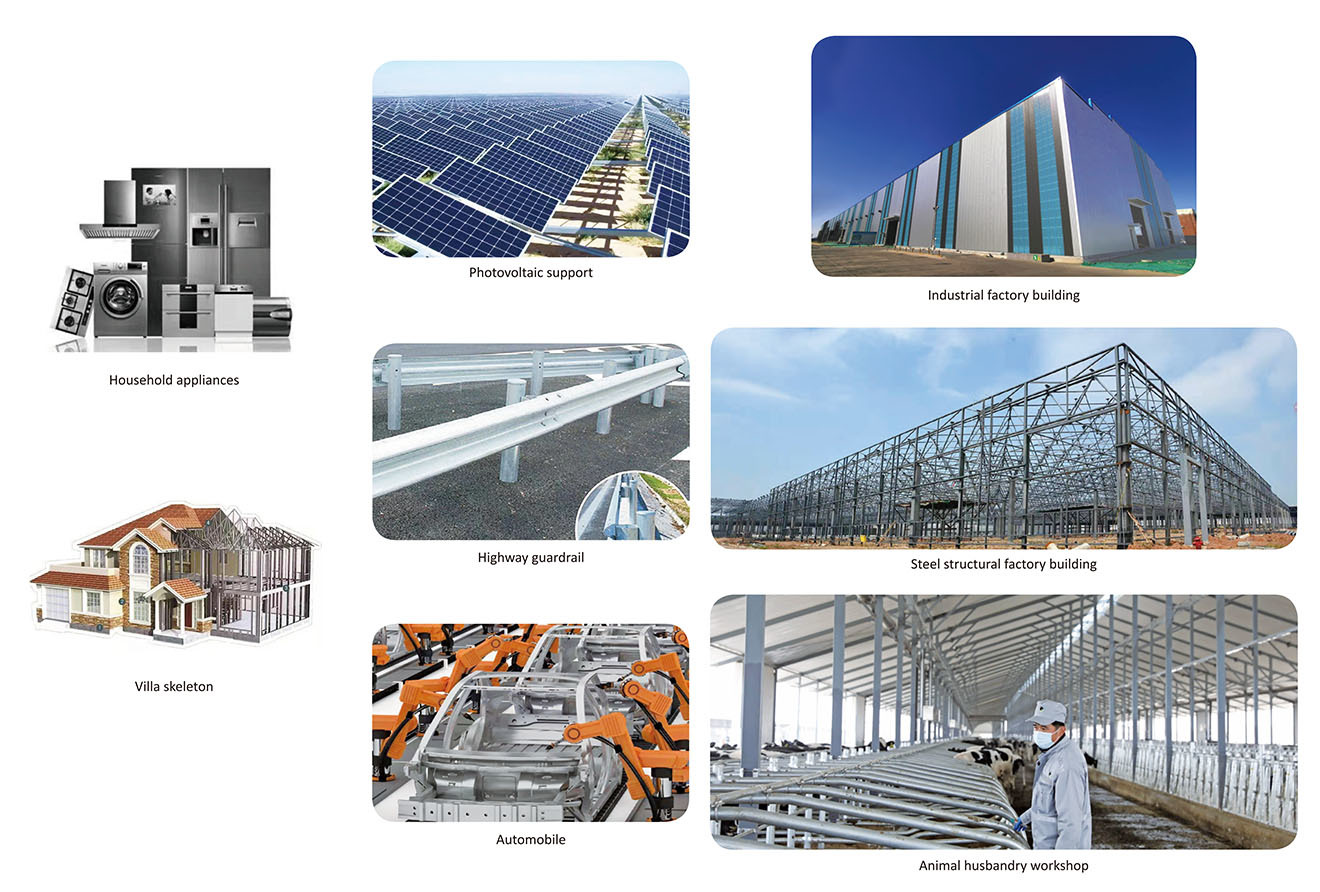

It is suitable for industrial construction,agriculture,animal husbandry buildings,railways,roads and bridges,power communication facilities,photovoltaic support,industrial facilities and many other fields.

Application of galvanized aluminum magnesium products

Galvanized aluminum magnesium steel plate is widely used in automobil,household aplinces,giulture,animal husbandry,transportation filtispower communication,photovoltaic supportindusrial rfrigeration,construction and many other fields.

Related Products

Product Consulting

Public account

ZhongAn (Qian'an) Steel Plate

Add: No. 6899 Qiguang Street, High-tech Industrial Development Zone, Qian 'an City, Hebei Province

Tel: +86-0315-5671599 / 5671699

Fax: +86-0315-5671799

Copyright © 2023 ZhongAn (Qian'an) Steel Plate Manufacturing Co., Ltd.